ZhongMaAerosol Valve Professional Customized

Experience the ultimate in aerosol dispensing with our ZhongMa Aerosol Valves. Designed for businesses seeking unmatched reliability and efficiency, these valves combine high-performance delivery with flexible customization. Tailor your aerosol valves to fit your specific needs and ensure your products perform flawlessly under any conditions. The precision engineering of our valves guarantees easy installation and durability, making them the perfect choice for your aerosol solutions, wherever they need to be deployed

Explore Our Product Range

From aerosol valves to plastic lids our products are crafted to meet your specific needs

General Applications for Aerosol Valves

Aerosol Valves are versatile components utilized across a broad spectrum of industries, showcasing their adaptability and efficiency. Our valves play a crucial role in numerous applications, ensuring reliable and precise performance in every use

Personal Care

- hair sprays

- deodorants

- shaving foams

Personal Care and Cosmetics: Aerosol valves used in products like hairsprays, deodorants, and other personal care items

Household Cleaning

- air fresheners

- disinfectants

- furniture polishes

Household Products: Valves for items such as air fresheners, insecticides, and cleaning products.

Food and Beverage

- packaging whipped cream

- cooking oils

- cooking sprays

Food and Beverage: Safe and reliable for packaging whipped cream, cooking oils, and other consumables that require pressurized dispensing.

Automotive and Industrial

- lubricants

- paints

- protective coatings

Automotive and Industrial: Aerosol valves for automotive products, paints,lubricants,coatings, and industrial maintenance.

Pharmaceuticals

- nasal sprays

- asthma inhalers

- sanitizers

Pharmaceuticals: Trusted for delivering medical aerosols such as inhalers and sanitizers, our valves ensure accurate dosing and contamination-free delivery, adhering to stringent health safety standards.

Choosing the RightAerosol Valve

When selecting an aerosol valve, consider the following factors:

Product Viscosity

Ensure the valve can handle the viscosity of your product.

Spray Pattern

Different products require different spray patterns (fine mist, jet stream, foam).

Dosage Control

Determine if precise dosage control is needed, such as with metered valves.

Application Environment

Consider where and how the product will be used (e.g., in hard-to-reach areas, on-the-go usage).

Compatibility

Ensure the valve materials are compatible with the product formulation to prevent any adverse reactions or degradation.

By understanding the different types of aerosol valves and their applications, you can make an informed choice to ensure optimal performance and customer satisfaction.

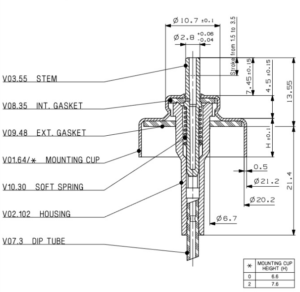

Types of Aerosol Valves

Aerosol valves are critical components in ensuring the effective dispensing of products from aerosol cans. There are several types of aerosol valves, each designed for specific applications and dispensing needs. Here are the main types:

1. Continuous Spray Valve

- Function: Allows for a continuous spray as long as the actuator is pressed.

- Application: Ideal for applications requiring a consistent and extended spray.

- Examples: Sunscreens, air fresheners, disinfectants.

2. Vertical Valve

- Function: Dispenses the product when pressed straight down.

- Application: Commonly used in everyday household and personal care products.

- Examples: Hair sprays, deodorants, cooking sprays.

3. Metered Valve

- Function: Dispenses a specific amount of product per activation.

- Application: Essential for products that require precise dosage.

- Examples: Medical inhalers, room fresheners, pharmaceutical sprays.

4. Bag-on-Valve (BOV) Valve

- Function: Uses a bag inside the can to separate the product from the propellant, allowing 360-degree dispensing.

- Application: Suitable for products requiring complete evacuation and preservative-free formulations.

- Examples: Sunscreens, topical sprays, food products.

5. Foam Valve

- Function: Designed to dispense products in a foam form.

- Application: Common in personal care and household products where foam application is needed.

- Examples: Shaving creams, foam cleansers, hair mousses.

6. Powder Valve

- Function: Specifically designed to dispense powders.

- Application: Used in products where fine powder dispersion is required.

- Examples: Dry shampoos, powder insecticides, foot powders.

7. Portable Gas Stove Valve

- Function: Provides precise control over the gas flow, allowing for fine adjustments to the flame.

- Application: Suitable for picnics, barbecues, and other outdoor events where portable cooking is needed.

- Examples: Portable camping stoves, backpacking stoves, emergency cooking kits.

Why Choose ZhongMa

Our Factory

Warehouse Center

QC Room

Punching

Stem Gasket Machine

Injection Molding

Aerosol Valve Assembling

Company Overview

Founded in 2010, we have rapidly established ourselves as a key player in the aerosol industry, specializing in the production of aerosol valves, actuators, aerosol cans, and plastic lids. Our commitment to quality, innovation, and customer satisfaction drives our approach, making us the preferred partner for businesses looking to enhance their products with reliable and efficient aerosol dispensing solutions.

Why Choose ZhongMa?

Based in Guangdong and exporting to countries across the Middle East, Asia, and beyond, we have the global reach to serve customers around the world. Our understanding of international markets equips us with the necessary expertise to meet your specific needs, no matter where you are located.

- Quality Assurance: With a robust quality control system, we ensure every product from our lines meets stringent standards.

- Scalable Production: From small batches to large orders, our advanced manufacturing capabilities can handle it all, without a minimum order quantity.

- Rapid Fulfillment: Our efficient logistics ensure that your products are delivered on time, every time, anywhere in the world.

Expertise and experience and commitment to quality

Our team is composed of specialists who have spent years honing their skills in aerosol technology. This deep industry knowledge allows us to design and produce superior aerosol valves, actuators, cans, and lids that meet the exact needs of our customers.

Quality is the cornerstone of our operations. We implement stringent quality control measures at every stage of our production process. From the initial design to the final dispatch, our QC team ensures that every product adheres to both international standards and client specifications.

Staying on top of aerosol technology

our corporate vision is to be at the forefront of the aerosol industry, setting standards in innovation, sustainability, and customer satisfaction. Our commitment to excellence in developing aerosol valves, actuators, canisters, and lids drives us to continually improve our products and processes, ensuring we meet the evolving needs of our customers worldwide.

- Cutting-Edge Research and Development

- Adaptation to Emerging Trends

- Commitment to Sustainability

THE ADVANTAGES OUR ARE IN THE QUALITY OF PRODUCTS

ZhongMa products are designed to comply with the strictest global regulatory standards. This commitment to compliance not only ensures the safety and quality of our products but also facilitates smoother market entry for our clients worldwide.

- Utilizing state-of-the-art technology, every product is crafted with precision, ensuring consistent performance and reliability.

- Each item undergoes stringent testing and quality assurance processes, guaranteeing that every product not only performs flawlessly but also maintains its integrity over time.

- Our products comply with international safety and quality standards, making them trusted choices in diverse markets worldwide.

YEAR EXPERIENCE

Successful trading

HAPPY CLIENT

Hear from Our Clients

Certifications

Staying on top of Aerosol Technology

Order Process Guide

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

1. Customer Intention Confirmation

When customers place orders through email or chat software, to avoid misunderstandings, please ensure the following:

- Clear communication of requirements and details

- Use formal written language to document customer requests

- Confirm information accuracy with the customer before proceeding to the next step

2. Product Confirmation

When confirming the product ordered by the customer, pay attention to the following details:

- Product Name: Ensure it matches the customer’s requirements

- Tube Length: Include the total height of the can (can body height + upper top cover height)

- Button Type: Choose the appropriate button type as per customer specifications

- Filling: Specify whether it is gas or liquid, and the exact type

3. Production Preparation

In the production preparation stage, ensure the following information is clear and agreed upon:

- Model: Confirm the specific model required

- Quantity: Verify the order quantity

- Delivery Date: Clarify the delivery timeline

- Address: Confirm the delivery address

- Price: Agree on the price with the customer

- Payment Method: Decide on the appropriate payment method

- Packaging Specifications: Confirm the specific packaging requirements

- Label Requirements: If there are special labeling needs, ensure they are confirmed before production

4. Order Confirmation

In the final order confirmation step, proceed with the following:

- Sign the Order Contract: Ensure contract terms are clear and mutually agreed upon

- Production Notification: For special labels or other requirements, promptly notify the production workshop

- Final Order Confirmation: Confirm all order details and proceed to production

Ready to Compress Your Lead Times?

Hurry up and contact us to tailor a plan specifically for your business needs.we understand the importance of reducing lead times to get your products to market faster. Let us help you streamline your production process and achieve quicker delivery times.

FAQs Throughout the Trading Process

we specialize in the production of high-quality aerosol valves, actuators, aerosol cans, and plastic lids. Our products are designed to meet the diverse needs of manufacturers and packagers in various industries.

Yes, our aerosol valves, actuators, and other accessories are designed to be easily disassembled for distribution. This feature facilitates the logistics of large orders and supports customers who require components for final assembly in different locations or under different brand names.

For our aerosol products, important parameters typically include:

1.Valve size and type (continuous, metered, etc.)

2.Actuator type (standard, custom shapes for ergonomic or aesthetic requirements)

3.Dispensing rate (important for consistency and precision in product application)

4.Compatibility (with various types of aerosol cans and contents)

5.Pressure specifications (to ensure safety and functionality under different conditions)

Our products are made using high-quality materials that meet international standards:

1.Valves and actuators: Typically made from aluminum, stainless steel, or plastic, chosen for their durability and resistance to corrosion.

2.Cans: Usually aluminum or tinplate, selected for their strength and compatibility with aerosol propellants.

3.Plastics: High-grade polymers are used for components that require flexibility and precision molding.

Our production testing includes several stages:

1.Leak testing: Ensures that valves and cans maintain integrity under pressure.

2.Performance testing: Confirms that the dispensing rate and spray pattern meet specified

3.Durability testing: Validates that the product will perform reliably over its expected lifespan.

Our production capacity can reach up to 1.8 million units per day, thanks to our extensive setup and dedicated workforce. This allows us to handle large orders efficiently and ensure timely delivery to our clients.

Yes, ZhongMa products are certified to comply with relevant international safety and quality standards, including ISO certifications. This ensures that our products meet both regulatory requirements and customer expectations globally.

We offer various packaging options to meet diverse logistics and branding needs:

1.Bulk packaging: For large volume industrial use.

2.Retail packaging: Customized to client branding and regulatory labeling requirements.

3.Sustainable packaging options: Available to support environmental goals.

Our standard payment process is straightforward:

1.Initial Deposit: Typically 30% of the total order value, required at the time of order confirmation.

2.Balance Payment: Due upon completion of production and before shipment. This can be adjusted based on contract terms and established client relationships.

In the event of a product error or defect, our error handling process includes:

1.Immediate notification: Clients are asked to report issues as soon as they are discovered.

2.Assessment and analysis: We conduct a thorough investigation to determine the cause of the defect.

3.Corrective actions: Includes replacement of defective items and adjustment of production processes to prevent recurrence.

4.Continuous improvement: Insights from error handling are integrated into future production enhancements.

Get My Free Sample

Send us an inquiry today and receive a complimentary sample tailored to your specific requirements

Comprehensive Aerosol Packaging Solutions

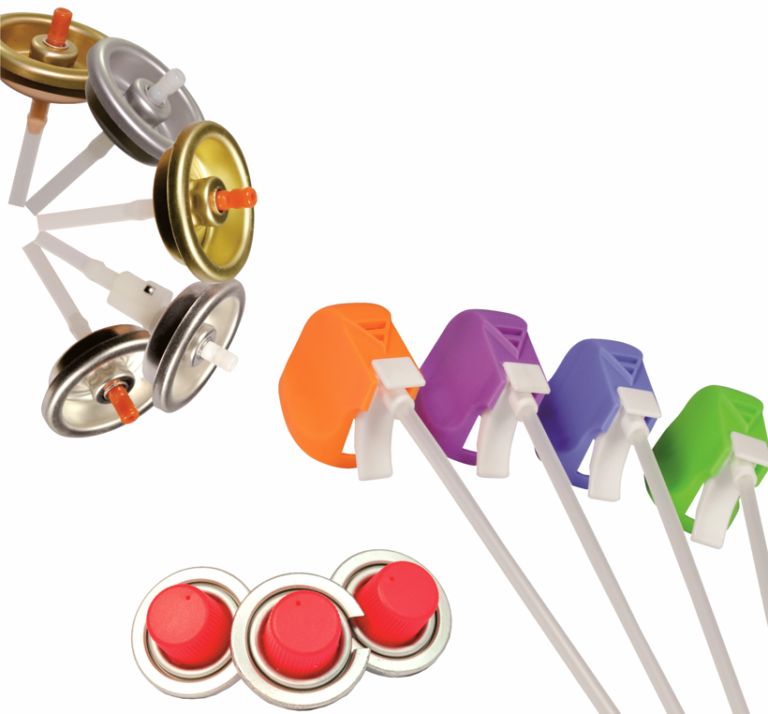

From valves to plastic lids, we offer a wide range of high-quality products tailored to your needs

- Aerosol Valves: Reliable and efficient

- Actuators: Precision-engineered for performance

- Aerosol Cans: Durable and customizable

- Plastic Lids: Versatile and high-quality