Are you curious about what an aerosol valve is and how it functions in everyday products?

Understanding the intricacies of aerosol valves can be complex, especially for those new to the industry.If you’re struggling to grasp how these small components play such a significant role in the functionality of aerosol products, you’re not alone.The confusion and technical jargon can be overwhelming.But worry not, as we break down the essential aspects of aerosol valves, making it easy for you to understand their importance and operation.

An aerosol valve is a critical component of aerosol products, enabling the controlled release of contents from pressurized containers. It functions as both a dispensing mechanism and a hermetic seal, ensuring that the product remains contained until needed. The valve’s design allows it to withstand high pressures and various formulations while preventing leakage when closed.

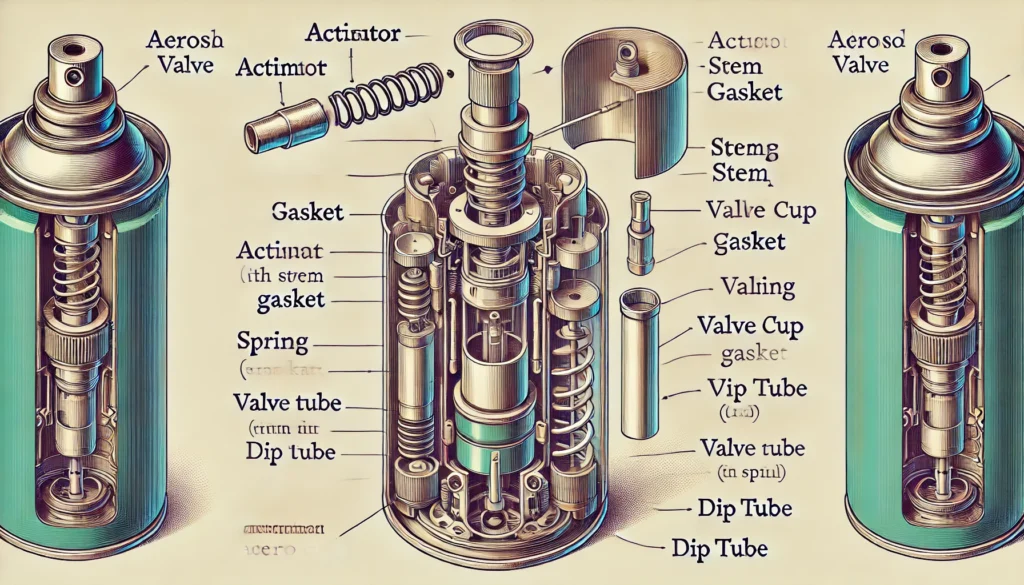

Key Functions and Components

Dispensing Mechanism

The valve allows for the controlled release of the aerosol contents when activated. This is typically achieved through an actuator that, when pressed, opens the valve and exposes the stem orifice to the pressurized product, allowing it to flow out.

Sealing Capability

When not in use, the valve seals tightly to prevent the contents from leaking. This hermetic seal is crucial for maintaining the integrity of the product over time.

Main Components

- Actuator: Controls the flow and pattern of the spray.

- Stem: Regulates the flow of the product.

- Stem Gasket: Acts as the “on/off” switch for the valve.

- Spring: Returns the valve to the closed position after use.

- Dip Tube: Draws the product from the can into the valve.

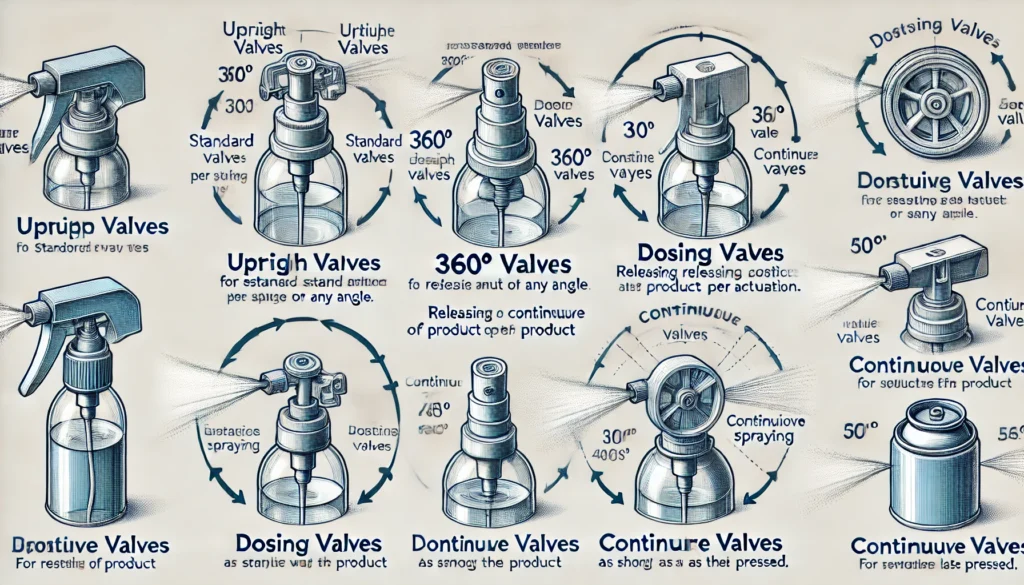

Types of Aerosol Valves

Aerosol valves come in various types, each designed for specific applications:

- Upright Valves: Standard valves for typical upright use.

- 360° Valves: Can spray from any angle, allowing for versatile applications.

- Dosing Valves: Release a specific amount of product per actuation, ideal for medical or precise applications.

- Continuous Valves: Allow for continuous spraying as long as the actuator is pressed.

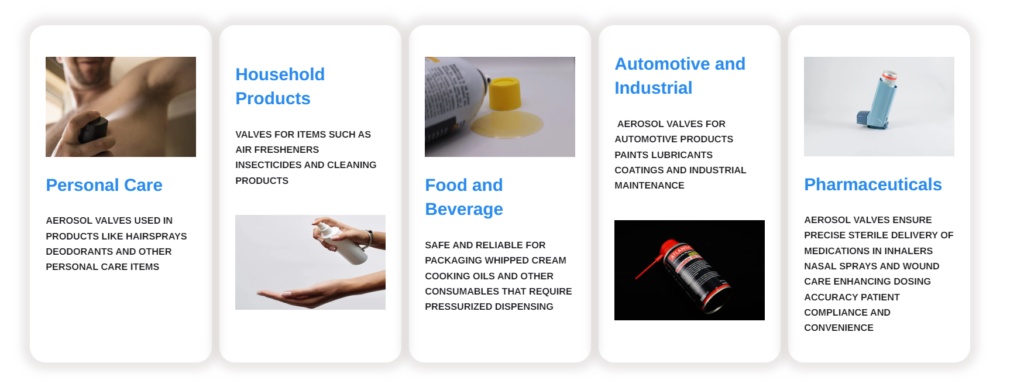

Applications

Aerosol valves are used in a wide range of products, including personal care items (like deodorants), household cleaners, medical sprays, and industrial applications. Their design and functionality have evolved significantly since the first aerosol can was developed in the 1920s, contributing to the convenience and effectiveness of aerosol products in daily life.

Understanding these basics is just the beginning. Dive deeper into the world of aerosol valves to learn about their various applications and the different types available.

What is Aerosol Used For?

Aerosols have diverse applications across various industries. In personal care, they are used for products like deodorants, hair sprays, and shaving foams. Household products include cleaners, disinfectants, and air fresheners. In the medical field, aerosols are used for inhalers and antiseptics. Industrial uses range from lubricants to spray paints. The versatility of aerosol products lies in their ability to deliver controlled and precise amounts of a substance in an easy-to-use form.

What is the Difference Between Aerosol and BOV?

Bag-on-Valve (BOV) technology is a type of aerosol system where the product is contained within a bag inside the can, separated from the propellant. This separation ensures the product remains pure and uncontaminated by the propellant. Traditional aerosols mix the product with the propellant, which can sometimes affect the product’s formulation. BOV systems offer advantages like 360° dispensing, longer shelf life, and the ability to use eco-friendly propellants.

What is an Aerosol System?

An aerosol system comprises the container, the product, the propellant, and the valve. The container is typically made of aluminum or steel. The product is the substance to be dispensed, while the propellant is a pressurized gas that helps expel the product when the valve is activated. The valve is the key component that controls the release of the product. When the actuator is pressed, the valve opens, and the pressurized propellant forces the product out through the stem.

What is the Function of the Actuator in an Aerosol Can?

The actuator is the user interface of the aerosol can. It is the part that you press to release the product. The actuator controls the flow rate and the spray pattern. By pressing the actuator, you open the valve, allowing the product to be expelled from the can. Actuators come in various designs, tailored to the specific needs of the product, such as fine mist sprays, foam dispensers, or targeted jets.

What is an Aerosol Valve Used For?

Aerosol valves are essential for dispensing a wide range of products in a controlled and efficient manner. They ensure the product is released in the desired form, whether it’s a fine mist, foam, or jet. The valves also maintain the integrity of the product by preventing leaks and contamination. Without aerosol valves, the functionality and convenience of aerosol products would be greatly diminished.

Aerosol Valve Types

There are several types of aerosol valves, each suited for different applications:

- Upright Valves: Used for standard upright dispensing.

- 360° Valves: Allow dispensing from any angle, ideal for hard-to-reach areas.

- Dosing Valves: Provide a measured amount of product with each actuation, perfect for applications requiring precise dosing.

- Continuous Spray Valves: Enable continuous spraying as long as the actuator is pressed, suitable for products like spray paints and insecticides.

Aerosol Valve Diagram

Understanding the components of an aerosol valve can be enhanced with a diagram. A typical aerosol valve includes the actuator, stem, gasket, spring, and dip tube. Each part plays a critical role in the valve’s function, from controlling the spray pattern to ensuring the product is drawn from the container efficiently.

Aerosol Valve HS Code

The Harmonized System (HS) code for aerosol valves is essential for international trade. It helps in the classification of goods for customs purposes. The HS code for aerosol valves is typically found under the heading for “Machinery and Mechanical Appliances,” which can vary slightly depending on the specific type of valve and its application.

Aerosol Valve Parts

An aerosol valve comprises several key parts:

- Actuator: The part you press to release the product.

- Stem: Connects the actuator to the valve body.

- Gasket: Seals the valve to prevent leaks.

- Spring: Ensures the valve returns to the closed position.

- Dip Tube: Draws the product from the can into the valve.

Aerosol Valve Assembly

The assembly of an aerosol valve involves fitting together all the components to create a functional valve. This process requires precision to ensure the valve operates correctly and maintains the integrity of the product. Proper assembly is crucial for the valve’s performance and the overall quality of the aerosol product.

Continuous Spray Valve

Continuous spray valves allow for a consistent spray as long as the actuator is pressed. These valves are used in products that require a steady and even application, such as spray paints and cleaning products. They offer convenience and efficiency, making them a popular choice for many applications.

Metering Valve Aerosol

Metering valves dispense a specific amount of product with each actuation. This is particularly useful for medical applications, where precise dosing is critical. Metering valves ensure that the correct amount of product is released each time, providing consistency and accuracy.

Summary

In conclusion, understanding the function and components of an aerosol valve is essential for appreciating its role in various products. From personal care to industrial applications, aerosol valves ensure the controlled and efficient release of products. Their design and functionality have evolved to meet diverse needs, making them a crucial component in the world of aerosols. If you have any further questions or need more detailed information, feel free to reach out to us at ZhongMa, where we specialize in top-quality aerosol valves and accessories tailored to your needs.

Contact: Luo | Email: luo693298@gmail.com | Website: www.zhongmavalve.com

Brand: ZhongMa | Country: China